Closing the loop on plastic packaging

Creating a circular plastic economy will take more than a ramp-up in recycling

1 minute read

Andrew Brown

Head of Plastics and Recycling

Andrew Brown

Head of Plastics and Recycling

Andrew is responsible for integrating our sustainability and recycling views across chemical value chains.

Latest articles by Andrew

-

Opinion

Can imports solve the plastic recycling challenge?

-

Opinion

Bottle battle: the fight for recycled plastic supply is on

-

Opinion

Closing the loop on plastic packaging

-

Opinion

Can the plastics industry decarbonise?

-

Opinion

Will coronavirus change the course of plastic circularity?

The plastic packaging industry finds itself as the poster child of unsustainable consumption. After decades of rapid growth – powered by plastic’s ability to cost-effectively protect and preserve products – the industry is now confronted at every turn by images of beaches clogged by its detritus.

So, can higher rates of recycling turn the tide of plastic waste? What role will product redesign play? And what does it all mean for industry growth? We explored the road ahead in our Circular plastic packaging report. Fill in the form for a complimentary extract, and read on for an introduction.

The push for a recycling ramp-up has begun

To their credit, many of the sector’s biggest brands have recognised the scale of the challenge, with some now pushing for a legally binding UN treaty on plastic pollution. Change is underway, but it needs to accelerate.

One of the key levers the industry is banking on to turn the tide on plastic waste is a significant ramp up in the use of recycled materials. By imbuing post-use plastics with value, recycling can help to direct plastic into new applications and out of the environment. By displacing virgin materials, recycled materials can leave fossil fuels unused and lower the value chain’s carbon footprint.

Can recycled material supply match plastics demand?

The question facing the industry is whether the availability of recycled materials can grow to meet demand, given the comparatively low levels of recycling today.

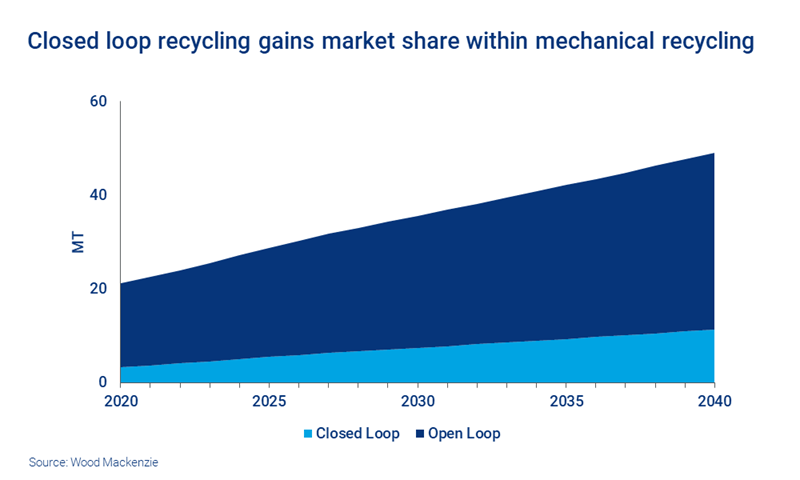

Mechanical recycling is responsible for more than 96% of all plastic packaging recycling at the moment. However, only 15% of this waste makes its way back into the packaging sector – and this is almost exclusively PET bottles. The rest is downcycled into other applications. We expect closed loop recycling to grow nearly twice as fast as open loop routes to 2040 – in a market that is growing faster than virgin plastic markets – but this is not enough to meet latent demand for recycled materials.

Chemical recycling could play an important role in tackling the plastic waste challenge

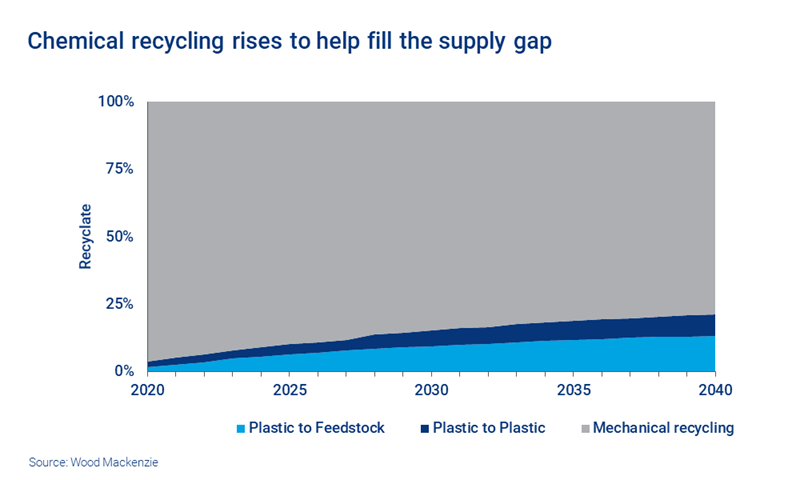

Chemical recycling technologies are stirring interest, thanks to their potential to make a wider selection of polymer and application types recyclable. While the technologies are still commercially nascent, 2020 and 2021 saw significant new announcements of projects that will become operational pre-2025. This investment feeds into a CAGR of more than 15% for chemically recycled plastic packaging up to 2040.

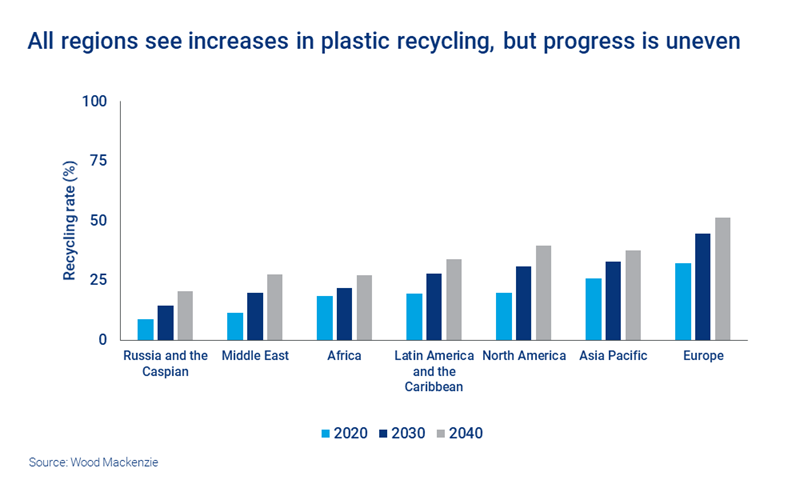

These routes in combination will see the amount of circular feedstock rise sharply, but the impact will not be felt uniformly across the world. Europe will remain the region with the highest recycling rate in 2040, with the stringent regulatory targets in the region driving recycling rates over 50% by the end of the forecast. North America will see the largest increase, with an increase of around 20 percentage points as consumer brands drive up the comparatively low recycling in the region today.

Recycling alone isn’t enough – plastic packaging redesign will also be key

While these trends suggest that the recycling industry is set to undergo a period of booming demand, this in itself will not be enough to ensure that plastic packaging reduces its negative impacts on the environment. Indeed, recycling is only one strand of the drive to a more circular economy. The industry must also focus its attention on other dimensions, such as the need to redesign packaging from the ground up to deliver the sustainable products their customers want.

We explored the future of the industry in detail in our recent Circular plastic packaging report. Fill in the form at the top of the page for a complimentary extract.