Tackling the textile industry’s carbon footprint

Textile and apparel reuse strategies will play a role in cutting greenhouse gas emissions – how will that impact virgin fibre demand?

1 minute read

Bruna Angel

Principal Analyst, Fibres

Bruna Angel

Principal Analyst, Fibres

Latest articles by Bruna

-

Opinion

Bottle battle: the fight for recycled plastic supply is on

-

Opinion

Tackling the textile industry’s carbon footprint

-

Opinion

Has Covid-19 left the apparel industry hanging by a thread?

Emma Liu

Senior Consultant and Research Analyst, Fibres

Emma Liu

Senior Consultant and Research Analyst, Fibres

Emma focuses on the Asian fibres market, where she closely follows prices and dynamics.

Latest articles by Emma

-

Opinion

Tackling the textile industry’s carbon footprint

-

Opinion

How the delayed Olympic Games disrupts Japan’s recycled fibre sector

Reduce, reuse, recycle is a well-known mantra. Most commonly, it is thought of with reference to plastic packaging, and the battle against unsustainable consumption. But fibre, textile and apparel value chains are also under growing pressure to significantly reduce their environmental impact.

Growing awareness of the cost of ‘fast fashion’ has seen big brands making commitments to sourcing recycled or other sustainably sourced materials and reducing reliance on virgin fibre. However, the issue stretches beyond simply the environmental cost of the clothes that we put on our backs: fibres are used in a multitude of applications, from agriculture to space exploration.

Can reduce and reuse help to address the textile industry’s environmental footprint? And how will the greater reuse of material impact the demand for virgin fibre and open loop recycled fibre? We explore these issues in our report, Mapping the polymer impacts of textile and apparel reuse. Fill in the form for a complimentary copy and read on for an introduction.

The environmental cost of fashion

A 2019 World Bank report estimated that the fashion industry accounts for around a tenth of global greenhouse gas (GHG) emissions. There are environmental costs throughout the value chain at production, use and disposal – however, the material production of textiles and non-woven fabric (including dying and finishing) accounts for the bulk of the apparel supply chain’s GHG emissions, according to a November 2021 paper from the World Resources Institute (WRI) and the Apparel Impact Institute (AII).

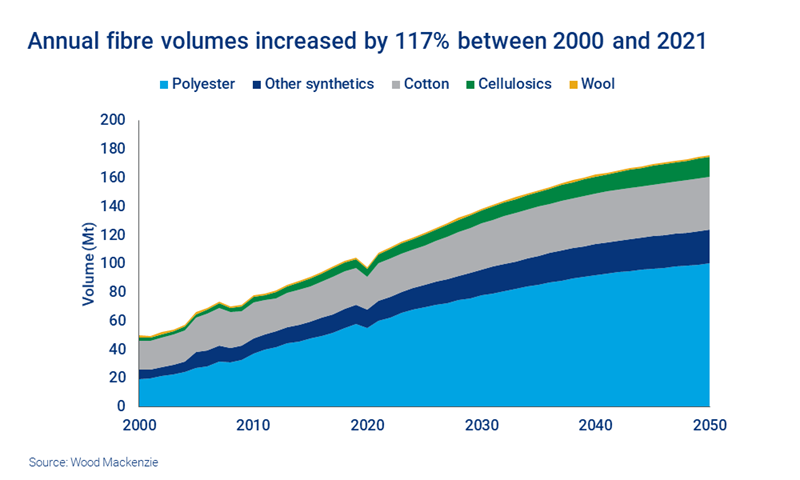

It’s an increasingly pressing issue, with annual fibre volumes more than doubling in the last 20 years.

Significant emissions reductions are possible – but the path ahead won’t be easy. The WRI and AII paper highlights the route to a 45% reduction in industry emissions, putting forward a number of recommendations:

- Energy efficiency and use of renewable electricity and elimination of coal-fuelled power stations.

- Product design and material selection to reduce waste and improve apparel longevity, reuse and fibre recycling.

- Increased use of recycled and bio-based fibres (recycled polyester derived from used bottles and conservation tillage for cotton).

What role could reuse play in reducing the apparel industry’s environmental footprint?

Resale and reuse of textiles and apparel is already a considerable business. Well-known websites such as eBay, Redress and Vinted and traditional charity shops or vintage shops have been outlets for second-hand textiles and apparel for some time. Many private sellers have used e-commerce to turn their hobbies into businesses, particularly during the Covid-19 pandemic.

Resale and reuse fit with requirements for greater circularity and waste reduction. And those are high up in the waste hierarchy, as they prevent waste and reduce resource use and emissions. But the key to their success lies in consumer attitudes. Some view second-hand goods as an affordable way to access items they would otherwise not be able to purchase. Others perceive them as low-income, welfare products.

In the UK, the estimated penetration of reused textiles and apparel in 2017 was 10% of the total market, based on WRAP research. In China, the estimated reuse penetration rate in 2019 was 0.3%.

How will greater reuse impact demand for virgin fibre?

Reusing textiles and increasing use of recycled and bio-based fibres, such as recycled polyester derived from used bottles, are two strategies to reduce the industry’s emissions.

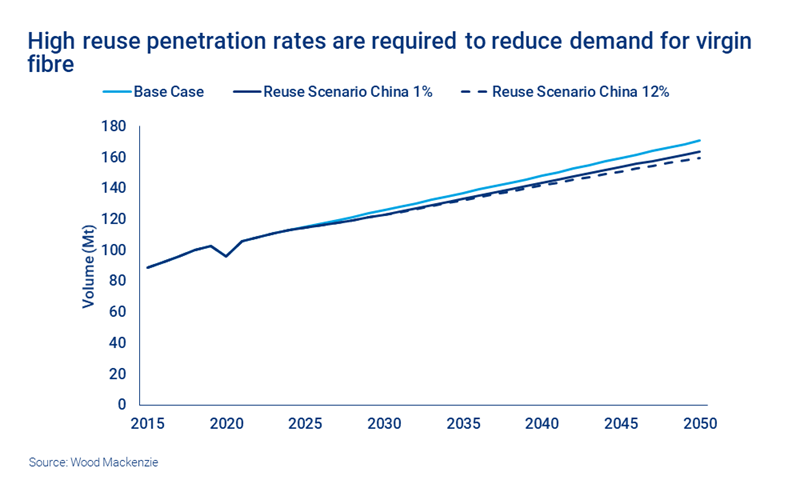

Reuse can make an impact on the environmental footprint of virgin fibre and open loop recycled fibre, but much depends on penetration rates.

We modelled penetration rates of reuse textiles and apparel across regions, with two distinct scenarios for China:

- A 1% penetration rate by 2050, based on current trends.

- A 12% penetration rate, which would require a step-change in consumer attitudes as well as the necessary infrastructure and regulation.

However, even the second scenario would have a limited impact on virgin fibre demand and would result in just a 6% reduction from our base case on a global level.

Reuse alone is not enough

Reuse is just one of the tactics that will be needed to address the apparel industry’s environmental footprint. Other mitigation strategies will be needed, such as chemical and mechanical recycling, which we explored in Closing the loop on plastic packaging.

To find out more, fill in the form at the top of the page for your complimentary copy of Mapping the polymer impacts of textile and apparel reuse. This includes charts on:

- GHG emissions in the apparel supply chain

- Per capita fibre demand

- International used textile and clothing trade: importers and exporters

- The impact of our modelled reuse scenario on wool, cotton, acrylic, polyester and more.