New recycling technologies can help solve the plastic waste problem

Giving new life to old plastic

1 minute read

Are there better ways to recycle plastic? At our recent Americas Polyester Conference, we explored whether chemical recycling can be part of the solution to our plastic waste problem. Read on to discover why guest presenter Dr. Sanjay Mehta of Indorama Ventures thinks chemical recycling has potential.

Sustainability has become a management issue. As awareness of improper plastic waste disposal grows, brand owners and retailers have put ambitious targets in place to increase the use of recycled content.

Governments are matching these aspirations by introducing single-use plastic bans and raising targets for PET collection.

While these goals are laudable, there’s one major problem: currently, recycling capacity and technology do not produce anywhere near the quality, or the quantity, of recycled plastic we need.

Can other technologies, such as chemical recycling, provide solutions?

First, what is chemical recycling?

It’s an innovative process that uses chemicals to break down post-consumer plastic waste into its valuable chemical components. These components can then be used as fuel, or converted once again into new plastic products. The process allows lower-quality post-consumer PET to be upgraded to virgin-grade resin, which has a higher value to the industry.

What are the problems with the recycling infrastructure we have now?

To start with, not enough plastic is collected. In the EU, the average rate of collection for PET stands at 58%: well below the 90% target that has been set for 2029. With big brands having pledged to increase recycled content in bottles by as much as 50% by 2030, over seven times the amount of recycled material will be required when compared to what is collected today across the EU.

Of the plastic collected for recycling in the US goes to landfill

And once the plastic is collected, not enough is recycled: 70% of the plastic collected for recycling in the US, and 30% in the EU, goes to landfill. On a global level, just 14% of plastic is recycled, with the majority ending up in landfill, as litter or incinerated.

The bottom line is that we need more recycling capacity and a better quality of PET supply to support current sustainability targets.

Three problems solved by chemical recycling

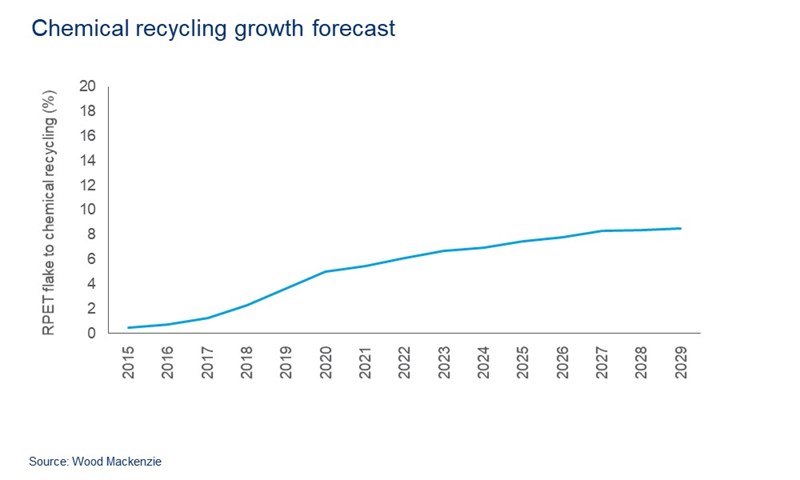

To get different results, we need to explore different solutions. Chemical recycling is new technology, and we’ve yet to see any major facilities at scale. However, it has the potential to be transformational by solving a host of problems.

- It produces higher quality plastic: Chemical recycling can provide a more reliable supply of clean clear flake with a higher bale quality, of the kind that brand owners need to meet recycled content targets.

- More types of plastic can be recycled this way: Many types of plastic are unsuited to current mechanical recycling processes. Chemical recycling means that low grade PET waste – typically sent to landfill – can to be turned into virgin raw material feedstock.

- Other waste materials can be recycled too: Carpet, fibres and other types of polyester are usually sent to landfill or incinerated. But with chemical recycling, these materials can be ‘upcycled’ to produce virgin-grade resin.

There is no silver bullet

While chemical recycling is as yet unproven as a technology, it shows promise.

Big brands are starting to explore its potential, and investments are being made – for example, the Shenzhen East waste-to-energy plant in China is due to come online in 2021 and will be the largest plant of its kind in the world.

Indorama Ventures takes this technology very seriously and is working with two startup chemical recycling companies, Ioniqa in Europe and Loop Industries in North America, to ensure the technology reaches its potential.

While chemical recycling is not a silver bullet to the plastic waste problem, it will be complementary to traditional mechanical recycling processes. Both methods of recycling should be embraced.

Dr. Sanjay Mehta is the Chief Technical Officer of the Recycling Business Group at Indorama Ventures, one of the largest producers of polyester products globally and an investor in chemical recycling technology. Fill in the form on the page for a complimentary extract of his slides.

Disclaimer: The views and opinions expressed in this article are the author's and do not necessarily reflect Wood Mackenzie's view.