Get in touch

-

Mark Thomtonmark.thomton@woodmac.com

+1 630 881 6885 -

Hla Myat Monhla.myatmon@woodmac.com

+65 8533 8860 -

Chris Bobachris.boba@woodmac.com

+44 7408 841129 -

Angélica Juárezangelica.juarez@woodmac.com

+5256 4171 1980 -

BIG PartnershipWoodMac@BigPartnership.co.uk

UK-based PR agency

Decarbonising global iron ore and steel industry by 2050 necessitates urgent action and US$1.4 trillion of investment

No ‘silver bullet’ with revolution required at every stage of industry value chain

3 minute read

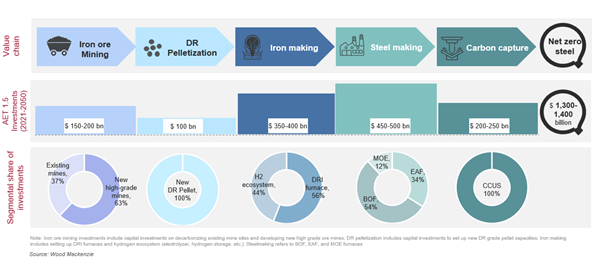

Decarbonising the steel and iron ore industry by 2050, in line with the Paris Climate Agreement, will require US$1.4 trillion of investment and revolution across every stage of the value chain. This presents an urgent challenge and enormous opportunity according to Wood Mackenzie’s latest Horizons research report, Pedal to the metal: Iron and steel’s $1.4 trillion shot at decarbonisation.

The analysis by Wood Mackenzie, a Verisk business (Nasdaq:VRSK), points to the industrialised world’s reliance on steel, with 2.2 billion tonnes of production required to meet global steel demand by 2050 – a 15% increase from 2021. From iron ore mining to steel manufacturing, the industry is highly carbon intensive. Iron and steel production emit a combined 3.4 billion tonnes of carbon annually - equal to 7% of global emissions.

Malan Wu, research director at Wood Mackenzie, and lead author of the report, said: “Decarbonising the steel industry is a staggeringly big task. To meet Wood Mackenzie’s 1.5 °C accelerated energy transition scenario by 2050, steel emissions must reduce by 90% from current levels. There is an urgent need to act now to decarbonise the iron and steel sectors. Business as usual is no longer sustainable.”

Iron and steel investments to reach net zero by 2050

Wood Mackenzie’s analysis sets out the revolution required at every stage of the industrial value chain, from mining to consumption, which presents an investment opportunity for operators as the industry works towards net zero by 2050.

Wood Mackenzie’s analysis shows US$800-900 billion will be essential to abate carbon from existing steelmaking infrastructure, such as setting up new hydrogen-based direct reduced iron (DRI) and electric arc furnaces.

Wu said: “Mining companies will need to play an active role in cutting their operational emissions as well as invest in new high-grade mines and green pellet capacities to feed green steel. In turn, this will require five times the current supply of high-grade pellet feed, an equivalent to 750 million tonnes, translating into an investment of US$250-300 billion.

“To achieve net zero by 2050, three-quarters of steel production will have to use low-carbon technologies, requiring the commercialisation and uptake of new technologies such as DRI and molten oxide electrolysis running on renewable energy. Switching to clean energy will also require around 2,000 gigawatts of dedicated renewable generation capacity, equivalent to two-thirds of current global renewable generation capacity.”

“A hydrogen ecosystem will also need to be developed for green steel, as decarbonisation will require around 50 million tonnes per annum of competitively priced green hydrogen, with commercial viability versus conventional steelmaking routes requiring green hydrogen supply at US$2/kg,” Wu added.

Carbon offset measures and a ‘green premium’ inevitable

The report warns that these measures will still fall short of emissions targets, necessitating an incremental US$200-250 billion investment in carbon offset measures, such as Carbon Capture, Utilisation and Storage (CCUS), as the industry will need to capture and store 470 million tonnes of carbon to reach its emission target in 2050.

Green premiums are also inevitable, given new technologies and low carbon feedstocks are likely to inflate steel production costs by 15-20%, in which steelmakers will pay approx. US$100 per tonne by 2050 to align themselves to a 1.5 °C goal by 2050, according to Wood Mackenzie estimates.

Wu added: “While steelmakers will have to swallow the price hikes for raw materials, carbon abatement costs will ultimately be passed onto steel end-users, meaning it is the consumer who must pay for the green premiums.”

Regional disparities will emerge

The iron and steel industry will also require support from global carbon policy. To date, most national carbon markets are nascent and concentrated in mature economies. As more than 60% of steel production comes from China, Beijing must implement aggressive carbon pricing and taxation if steel’s high carbon footprint is to be addressed.

Wu said: “Regional disparity will emerge, as a global response looks unlikely. Carbon mitigation tactics and strategies will vary widely, with mature economies - such as the EU, the US, Japan and South Korea - spending 50% more than emerging economies. Mature economies will also decarbonise much faster incurring a higher carbon abatement cost.”

“The transition to net zero calls for collaborative action globally and a unified approach across the value chain to turn risks into opportunities,” Wu concluded.