Discuss your challenges with our solutions experts

5 ways the wind industry is evolving

presenting endless new opportunities in need for innovation

1 minute read

Wind technology is on its way to becoming the world’s lowest-cost power source. Ever-increasing turbine components are continuously adding pressure on wind turbine OEMs. We've identified five trends wind developers need to keep in mind right now:

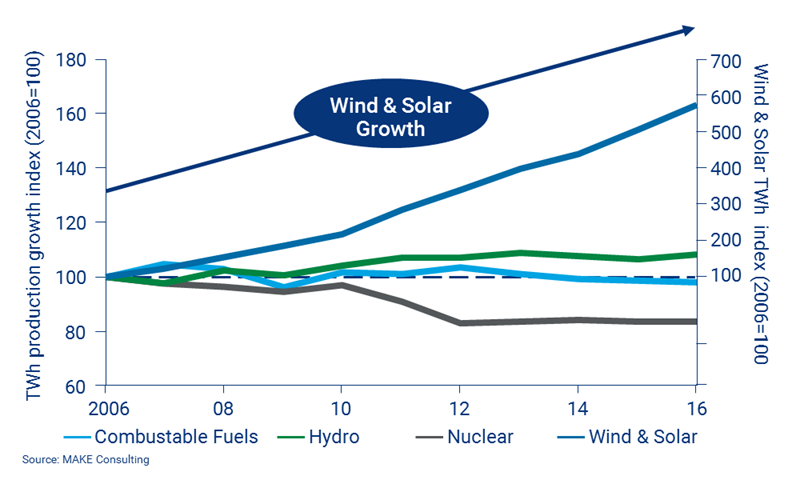

Renewable energy growth vs. fossil fuels

Note: Includes production levels from OECD countries only. Values are indexed to 2006 production levels. Source: IEA, MAKE

1. Adjusting to bigger and better blades

Wind turbines and associated equipment are evolving at a rapid speed. Turbines have grown larger in size, are more productive, more cost-effective and more reliable. Wind turbine OEMs are pressured to keep pace with these bigger and heavier products and will have to adapt to constant change to stay competitive in coming years.

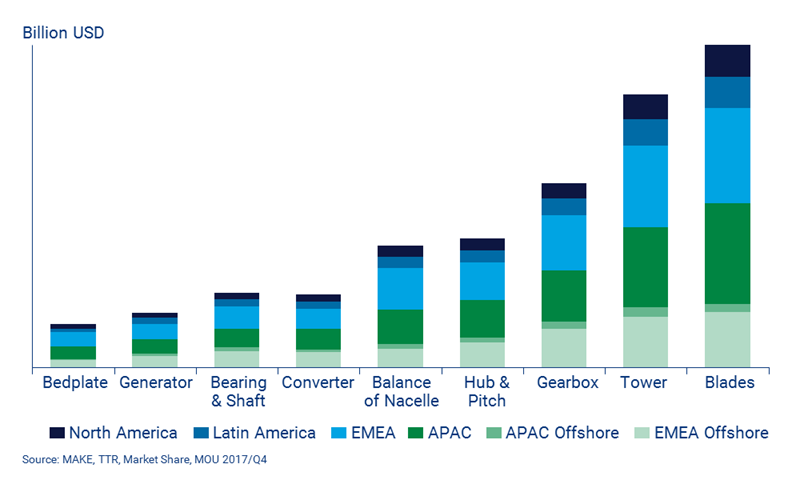

Total available market opportunity for strategic component supply, global, 2017-2025e

Note: Total demand from 2017-2025 is 592MW, and the market opportunity for supply is based upon the region where the turbines are grid connected. Source: MAKE

2. Accommodating for evolutionary technology shifts in offshore wind turbines

Advancing even quicker than its onshore wind turbine counterparts, the offshore wind market witnessed a record number of new product announcements, especially in China. Coupled with policy announcements enabling offshore wind installations in the US, the industry is picking up speed rapidly.

3. Focusing on maximizing product volumes as labour cost increases worldwide

Most new supply chain investments are driven largely by labour as cost. This has resulted in turbine OEMs migrating to cheaper markets as they are pressured to create sufficient economies of scale. But even traditionally lower-cost markets like China are facing increasing labour cost, so in the long run, turbine OEMs will have to increase product volumes.

4. Catering to Tier ll/lll markets

Major turbine OEMs are continuously looking for ways to maximize their global return on invested capital (ROIC) while also capturing market share in smaller and emerging markets such as Mexico, Canada and Australia. Traditionally, OEMs have taken on a 'cookie cutter' approach, which is becoming less ideal by the minute. Rather, OEMs need to innovate and develop specialized practices to match the next generation wind turbine models.

5. Finding new ways to maintain positive momentum

The wind energy industry has been eager to deliver maximum performance at the lowest possible cost. Turbine technology has advanced rapidly along the way, but as the latest generation of +4MW turbines is facing permitting issues, turbine innovation is expected to stall. To maintain the positive momentum of wind energy, the industry will need new concepts.

Explore these points in more detail through reports on Global Wind Turbine Supply Chain and Global Wind Turbine Trends from MAKE.