How green can steel go – and what does it mean for coal and iron ore?

Steel is on a mission to decarbonise, but it could be more evolution than revolution

1 minute read

At close to 10% of global emissions, the steel industry is under pressure to clean up. Increasing carbon costs and stringent environmental investment criteria have spurred a race to develop a zero-carbon steelmaking process. New technologies are advancing slowly, but with enormous implications for costs and raw materials.

So, what does the path to green steel look like – and what does it mean for metallurgical coal and iron ore?

A panel of Wood Mackenzie experts discussed this topic in a recent webinar. If you missed it, fill in the form on this page to listen to the replay. Or read on for an overview of some of the discussion points.

Scrap is the cornerstone of green steelmaking

Virgin ironmaking is emission-intensive, so the first logical step to reduce emissions is to reuse available scrap. But scrap cannot meet all metallics requirements – stock is limited, collection infrastructure is fragmented, and scrap quality can restrict recycled steel’s use.

Crucially, Scope 2 emissions for electric arc furnaces (EAFs) can be high without access to renewable energy. While power generated by renewables is accelerating, it is likely to remain a small portion of that supplied to EAF plants.

Virgin iron production will be required

Even with higher scrap utilisation, virgin iron production – with its often inevitable CO2 emissions – will be required to make steel.

The two main ways to produce iron will follow different paths to decarbonisation. The first – including blast furnaces – is smelting. Numerous approaches target a reduction in smelting emissions, but most only offer marginal gains because coal is an integral part of the process. And yet, as the most cost-competitive way of producing iron, smelting will be needed to meet metallics requirements. Here emissions are unavoidable and technology development is focused on capture and reuse of CO2.

The second way to produce iron is through direct ore reduction using gas. Syngas and natural gas have long been used in these processes, but the focus has now shifted to the use of hydrogen, which offers near-zero Scope 1 emissions. However, at the moment it is a trade-off with higher Scope 2 emissions from hydrogen produced from natural gas. Low-carbon hydrogen will have to scale up massively before it can offer meaningful emissions-reduction in the steel industry.

Further down the line, when access to renewable energy is ample, electricity-intensive electrolysis will become a viable technology for steel production. Overall, steel decarbonisation will be a technological evolution where three levers will come into play – scrap, alternative ironmaking and carbon capture.

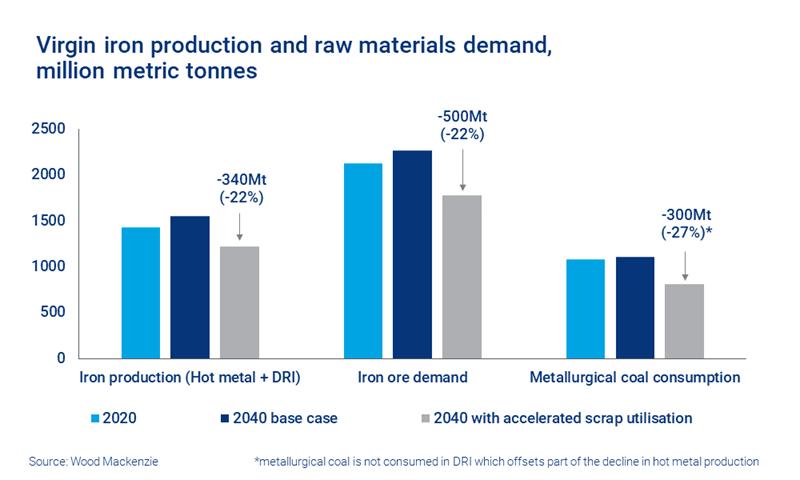

Increased scrap use could erode metallurgical coal and iron ore consumption

Metallurgical coal is the primary driver of CO2 emissions in virgin iron production. Coal demand will decrease when environmental concerns come to the forefront of policy. High-cost miners exporting to Atlantic basin customers will be most at risk.

Not all iron ore is equal – producers of blast furnace feedstock would be hit hardest by aggressive acceleration in scrap adoption. The result will be an industry even more dominated by the "Big 4" iron ore majors: Vale, Rio Tinto, BHP and Fortescue Metals. Many small players, especially those producing low-grade ore, would struggle to survive unless they were captive to (green) steel producers.

In contrast, with alternative ironmaking rising, demand for DR-grade iron ore feedstock could increase. However, pellet and pellet feed supply would struggle to grow at pace and supply shortages could be another hurdle for alternative ironmaking adoption.

Decarbonisation is a colossal challenge for the steel industry. Higher scrap use, even with its difficulties, is the simplest way to reduce emissions. Alternative, low-carbon, ironmaking will gradually evolve but financing, hydrogen supply, carbon capture and suitable iron ore grades are the necessary enablers for it to become mainstream. We expect to see a gradual technological evolution, not a revolution.

A cross-commodity view of the challenges of steel decarbonisation

In a recent Wood Mackenzie webinar, a panel of experts explored the path to green steel. If you missed it, listen to the replay to hear our discussion of topics including:

- The role of renewables, hydrogen and carbon capture in the energy transition

- Scrap’s potential to displace virgin iron ore

- The cost of emission reduction

- The outlook for global metallurgical coal and iron ore consumption.

Fill in the form at the top of this page for complimentary access to the webinar replay.