The entire Permian production cost curve is shifting as produced water volumes expand, posing a risk to production growth in the most prolific US shale play.

A lack of adequate investment and planning around water management could be detrimental to Permian E&Ps. While the associated costs vary depending on a producer’s geography and strategy, spend on the issue is growing alongside produced water volumes.

Like any other problem in the unconventional oil market, there’s no one-size-fits-all solution. E&Ps’ decisions to utilize self-build, third-party solutions or a combination of the two will depend on several factors.

We estimate daily produced water volumes in the Permian are about double that of crude output. This year, we see water volumes just above 10 million b/d. Water output will nearly double in the next four years, until declines emerge in the mid 2020s as activity shifts back to the Midland Basin.

Here are three reasons why Permian produced water could interfere with crude oil output:

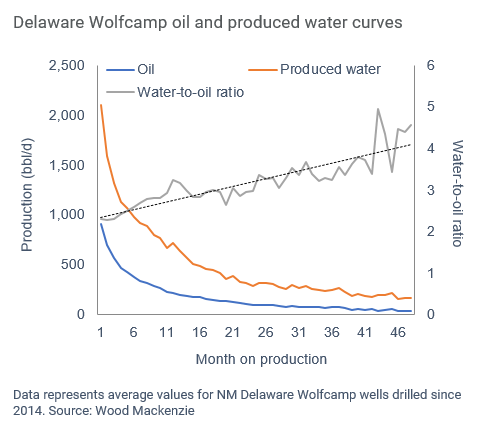

1. Permian produced water increases over time

Produced water has to either be injected into saltwater disposal wells, or be treated. As demand increases for enhanced completions, larger and larger volumes of water are flowing back to the surface.

Produced water has to either be injected into saltwater disposal wells, or be treated. As demand increases for enhanced completions, larger and larger volumes of water are flowing back to the surface.

Furthermore, multi-pad developments are resulting in a higher concentration of produced water in a single geography.

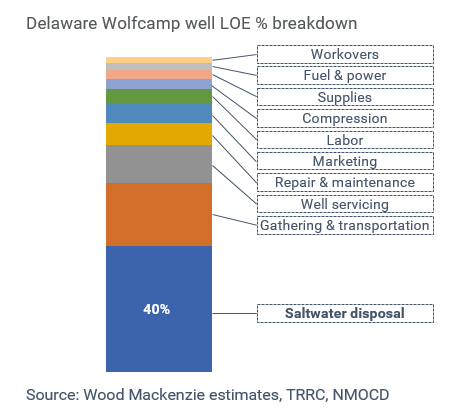

2. Permian water management is getting costlier

Saltwater disposal costs are estimated at 40% of total Delaware Wolfcamp well lease operating expenses. To target a deep injection formation more than 14,000 feet for saltwater disposal, the cost can surpass $10 million a well.

As the Texas Railroad Commission and New Mexico Oil Conservation Division work through a backlog of permits, the process is slowing. Shallow wells are not being approved at all in New Mexico, and additional regulations could be on the way.

3. Considerable water infrastructure buildout is needed

Traffic and road conditions in West Texas have made water trucking both expensive and unreliable.

Traffic and road conditions in West Texas have made water trucking both expensive and unreliable.

A comprehensive produced water management strategy would shift away from trucking growing volumes. Long-haul water pipeline construction is underway as operators build out their own facilities.

Congestion and trucking constraints have made the economics of produced water re-use programs more attractive. As injection capacity isn’t guaranteed with a saltwater disposal well, recycling systems are far more reliable.

This is just a taste of Ryan Duman's upcoming presentation at the Unconventional Resources Technology Conference in Denver on 24 July. His presentation, “Permian Produced Water: Impact of Rising Handling Costs and Larger Water Cuts on Wolfcamp Growth,” takes place at 9:20am in Room 601/603.

Need a pass to URTeC? We've got you covered. Fill in the form on this page to receive an exhibition pass on us.