Quantifying battery raw material demand

Accelerating electric vehicle sales continue to dominate battery raw material demand – while stationary energy storage applications are growing fast

1 minute read

Kevin (Gunan) Shang

Principal Research Analyst, Energy Storage Supply Chain and Technology

Kevin (Gunan) Shang

Principal Research Analyst, Energy Storage Supply Chain and Technology

Kevin leads leads research and analysis on the energy storage supply chain and technology.

Latest articles by Kevin (Gunan)

-

Opinion

Energy storage technology: three trends to watch

-

Opinion

Sustainable smelting: how green can it go?

-

Opinion

Quantifying battery raw material demand

The energy transition starts and ends with metals. Be it for electric vehicles (EVs) or stationary energy storage applications, the shift to a lower-carbon future requires batteries, and batteries require metals.

In a presentation at the recent Future Facing Mined Commodities Forum, we drew on insight from our Battery Raw Materials Service to explore how metals demand is set to test the battery supply chain in the coming years. Fill in the form to access a complimentary copy of our presentation, and read on for an introduction.

Continued surge in demand for EVs

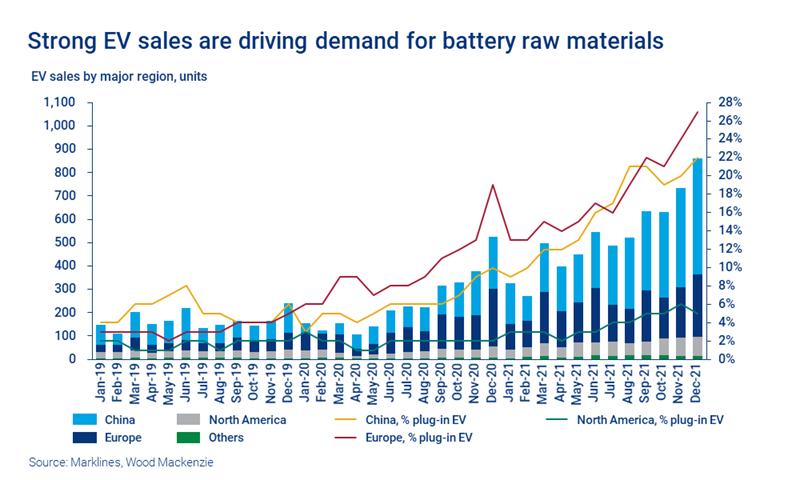

EVs account for the lion’s share of battery raw material demand and will continue to do so for some time. EV sales saw incredible growth in 2021, more than doubling to 6.5 million-plus units globally. Sales were particularly strong in the world’s two key markets, Europe and China, which bought a combined 84% of all electric passenger cars.

Both regions have benefited from a carrot-and-stick subsidy and incentive approach. Europe uses CO2 emissions regulations to encourage EV sales, while China uses a combination of quotas and emissions credits. The results are the same: automakers simply cannot meet emissions regulations without a high share of EVs in their portfolios.

This year will see the planned phase-out of some of these schemes, with both Europe's EV emission super credits and China's generous cash subsidies coming to an end. Obviously, the roll-back of these subsidies may crimp consumer enthusiasm a little, but we still see EV sales growing to 18-19% of all car sales in both regions in 2022.

Further out, we expect battery EVs and plug-in hybrids to account for 16% of passenger car sales globally by 2025 and 29% by 2030. This is a little conservative, perhaps, compared with other market forecasts, but we think many in the sector are ignoring the metals demand that must be met for these forecasts to materialise.

Lithium-ion to dominate the battery market

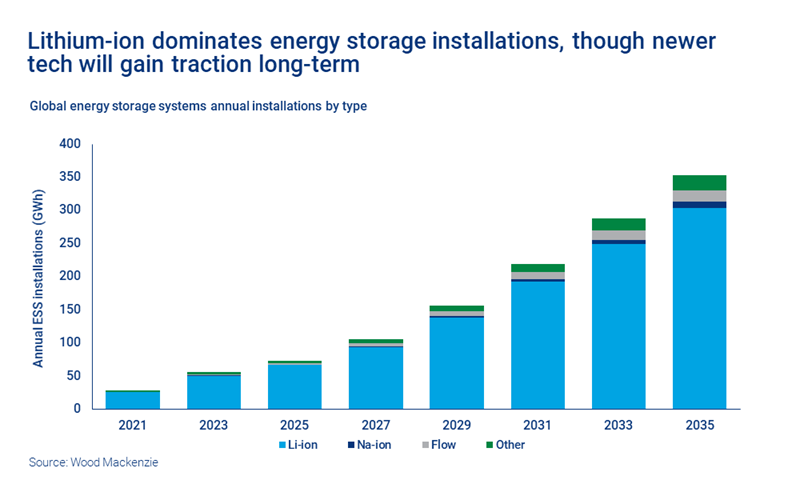

Stationary energy storage solutions are a fast-growing area for batteries. Here, as in the EV sphere, lithium-ion batteries dominate, accounting for more than 90% of applications. Down the line, alternatives such as sodium-ion batteries are likely to feature more heavily, as are some longer-duration options, like flow batteries.

With the increase in market penetration of lithium-ion battery technology in different applications, the demand for cathode materials will keep rising. Currently, five types of cathode material are the go-tos for lithium-ion batteries: cobalt (LCO), manganese oxide (LMO), iron phosphate (LFP), nickel-cobalt-aluminium oxide (NCA) and nickel-cobalt-manganese (NCM). Each has its advantages, and they will continue to be used in diverse ways.

NCM and the LFP are the most common in EV batteries – the latter has cost competitiveness and safety benefits, as well as better lifecycle performance. A typical disadvantage of LFP battery is its relatively low energy density. And that’s the main reason why NCM has been the preferred cathode chemistry: higher energy density gives EVs a longer driving range. However, the market has been evolving rapidly and LFP has seen increasing interest since 2020.

LFP batteries on the rise in China

In China, in July 2021, the installed capacity of LFP batteries actually started to outpace that of NCM and NCA batteries. As well as the advantages of LFP cathode chemistry, a combination of factors such as policy change, technological improvements and the patent landscape have led to its resurgence.

In 2019, the Chinese government changed its policy of financial subsidies for new energy vehicles and no longer blindly encourages higher energy density. Rather, its new policy puts greater emphasis on safety performance, suggesting a broader application space for LFP batteries. The end of China’s subsidy for new energy vehicles by the end of 2022 is likely to motivate EV and battery makers to find other ways to reduce costs further, highlighting the cost advantage of LFP chemistry.

We forecast demand for LFP cathode chemistries to reach about 3.1 million tonnes in 2035, more than 13 times the demand in 2021. The growth will come mainly from EVs and storage applications.

Get closer to the detail

Want to hear more about the demand outlook for battery raw materials? Our presentation Quantifying battery material demand in a fast-evolving sector includes charts on:

- Global energy storage systems annual installations by type

- Lithium-ion battery demand by end use segment

- Cathode demand by chemistry

- Announced LFP cathode capacity expansion by country

- And more

Fill in the form at the top of the page for complimentary access to the presentation replay and accompanying slides.