Chemical solutions: can chemical recycling improve the sustainability of the chemicals value chain?

*Please note that this report only includes an Excel data file if this is indicated in "What's included" below

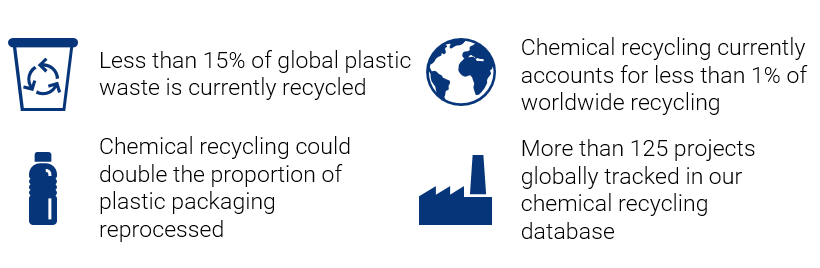

How chemical recycling can have a material impact on global recycling rates

With 220 million tonnes of plastic waste generated every year, industry, governments and brand owners are under pressure to become more sustainable. Nascent technologies have the potential to take plastic out of the waste stream and move it further up the value chain.

In this insight, the second part of our Chemical Solutions series, we explore the development of chemical recycling and how it can dramatically cut the levels of plastic sent to landfill, incineration or leaked into the natural environment.

Inside this report:

- For and against: the key benefits of chemical recycling – and the critics’ view.

- Chemical breakdown: how the separate chemical recycling processes work – purification, depolymerisation, pyrolysis and gasification.

- Creating value: where chemical recycling can save costs – and where it adds the most value.

- Growing industry: what will it take to increase the role of chemical recycling?

Want to know more about what's in this report?

Contact us via the form at the top of the page.

Did you know?

Chemical recycling creates more high-value recycling

One of the main driving forces for chemical recycling is its potential to unlock value in waste previously regarded as difficult to recycle.

Black PET trays are considered low value, because the black dye prevents them from being used in many PET applications. Chemical recycling removes the colouring, making this highly recyclable material much more valuable.

Products are (theoretically) infinitely recyclable

Mechanical recycling requires a flow of high-quality feedstock that must be sorted, cleaned, heated and reprocessed. The process often results in the plastic waste being ‘downcycled’ (where the final application is of a lesser quality than the original product). There are also limits to how many times polymers can go through the process before being unusable.

With chemical recycling, there is no limit on how many times a product can be reconverted into new applications or transformed into high-quality feedstock at the top of the value chain.

Find out more about plastic-to-plastic (P2P) and plastic-to-feedstock (P2F) recycling technology in the full Insight.

Chemical recycling can be a tool to reduce mismanaged plastic waste

The highest proportion of plastic waste generated each year is not sent to landfill or even incinerated. Around 40% ends up polluting the natural environment through mismanagement.

With chemical recycling technologies widening the range of what is economically feasible to recycle, waste-to-energy and landfill sectors can focus on drawing in more of the plastic that leaks out of the system.

Got a question about this report?

Our team will be happy to answer your queries. Get in touch by filling in the form at the top of this page.

Report summary

Table of contents

- Gives value to difficult to recycle plastic waste

- Another tool to reduce mis-managed plastic waste

- Greater potential to use lightweight flexible packaging applications

- Reduces fossil fuel extraction

- Reduces CO2 emissions

- Chemical recycling generates large emissions associated with its energy intensity

- Chemical recycling leaves toxic by-products

- Chemical recycling is simply a form of ‘wishcycling’/ greenwashing

Tables and charts

This report includes the following images and tables:

- Key differences between chemical and mechanical recycling

- Comparison of carbon dioxide emission equivalent for 1 kg of LDPE

- Examples of cross-value chain partnerships

- ‘Best option’ for end of life disposal of US plastic packaging, 2019

- Chemical recycling can double the proportion of plastic packaging that is reprocessed

- Integration/value chain options for chemical recycling facilities

- Projects by country/ region tracked in Wood Mackenzie’s chemical recycling database

- The chemical recycling industry is nascent, with few facilities operating at a large scale

- P2F technologies are attracting the most attention today

- Earlier stage projects are proportionately more focused on ‘shortening the loop’

What's included

This report contains: